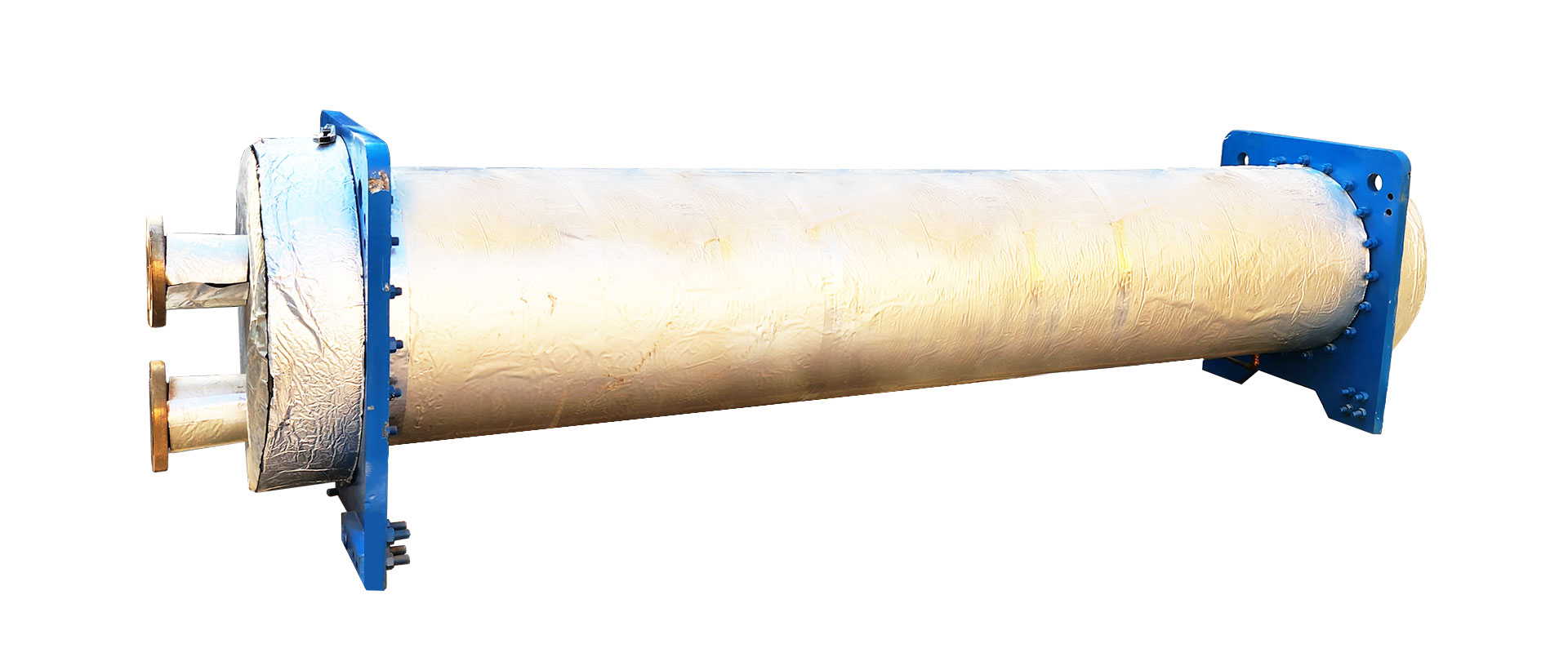

U Type Evaporator

U Type Evaporator

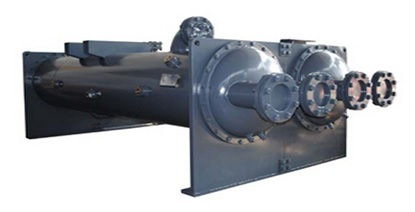

Flooded Evaporator

Flooded Evaporator

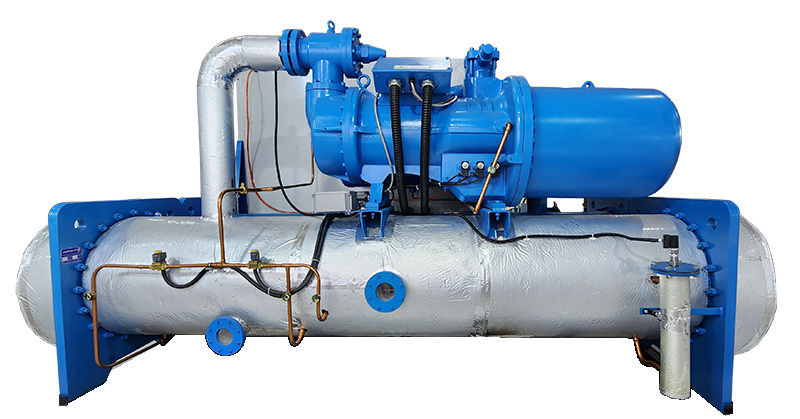

Oil Cooler

Oil Cooler Heat Exchanger

Condenser

Condenser Heat Exchangers

Filter Driers

Filter driers

How a Flooded Evaporator Works

In a flooded evaporator, the refrigerant enters the shell from the bottom. As it absorbs heat from the water flowing through the copper tubes, it vaporizes. The vaporized refrigerant exits from the top of the shell, while the liquid refrigerant remains at the bottom, continuing to absorb heat from the water to vaporize. Notably, approximately 70% of the shell’s volume is occupied by liquid refrigerant. This allows the liquid refrigerant, concentrated at the bottom, to have ample opportunity for complete heat exchange with the water inside the tubes. A combined control system (refrigerant level controller and electronic expansion valve) maintains an optimal refrigerant level in the shell to ensure efficient heat transfer between the refrigerant and water.

1- Gravity fluidized bed exchangers

2- Spray fluidized bed exchangers

2- The capacity and input power required by a screw compressor for two types of flooded and DX evaporators. Under the same conditions, the flooded chiller compressor will have a capacity of about 13.1% higher by receiving only 3.6 kW more input power, which means a higher EER (Energy Efficiency Ratio), or in other words, less energy consumption to create a certain refrigeration tonnage.

3- Given that the biggest problem with evaporators over time is the formation of deposits and blockages in the water path, which reduces the efficiency of the system, if water flows through the pipes (instead of the shell), for periodic services, it is only sufficient to open the inlet and outlet connections of the copper pipes and easily clean these deposits by mechanical or chemical methods (electric brushes, etc.).

1- If the same compressor is installed on both fluidized bed and DX evaporator systems, we see higher system capacity and higher EER in the fluidized bed chiller. Due to the immersion of the water pipes in the liquid refrigerant and the high heat transfer between the boiling refrigerant and the water, the temperature difference between the refrigerant and the water exiting the evaporator is about 1.5 °C. While this temperature difference between the refrigerant and the water exiting the DX evaporator is about 4 to 5 °C. As a result, when the outlet water temperature in both systems is set to the same degree, the refrigerant entering the fluidized bed chiller compressor will have a higher temperature.

Due to their higher efficiency compared to DX evaporators, flooded evaporators are more cost-effective for larger tonnage chillers. As a result, they are primarily used in high-capacity chillers.

Flooded chillers achieve a higher coefficient of performance (COP) due to their higher evaporation temperature compared to direct expansion chillers. However, for chillers with a capacity less than 150 tons, the construction cost and material consumption of flooded chillers are significantly higher than direct expansion chillers. Despite the higher efficiency of flooded chillers, most engineers and consultants still prioritize initial costs over energy consumption. Therefore, they typically choose direct expansion evaporators for capacities below 150 tons of refrigeration and flooded evaporators for capacities above 200 tons.

As a manufacturer of various shell-and-tube heat exchangers, Asamobadle Caspian has extensive experience in designing, manufacturing, and commissioning a significant number of flooded evaporator exchangers for renowned HVAC manufacturers in the country.

Additionally, our experience in repairing and refurbishing flooded evaporators used in imported chillers over the years has provided us with valuable insights into the strengths and weaknesses of major global manufacturers.

As a guideline, it is recommended to use flooded evaporators for capacities exceeding 200 tons. Moreover, if you are a chiller manufacturer who is not fully proficient in the control logic and automation of centrifugal compressors and the precise oil management control in screw compressors, it is advisable to avoid using this type of evaporator in your projects.

1- Higher Refrigerant Charge: Flooded chillers require a significantly larger amount of refrigerant. This is because the refrigerant must fill the evaporator shell and surround the water tubes. As a result, the chiller’s cost increases, making it one of the primary reasons for its limited use.

2- Complex Oil Return: Due to the submersion of the refrigerant and compressor oil within the shell, controlling the oil return is one of the most critical and challenging aspects of designing and manufacturing flooded evaporators.

3- Larger Footprint: Flooded evaporators are generally larger in size compared to DX evaporators of similar capacity, requiring more installation space.